Chemistries Developed

Our Flow Chemistry Process Development Lab is equipped with six walk-in fume hoods, a standard fume hood, and a dedicated analytical lab, providing a well-equipped environment for process development and optimization.

Our multidisciplinary team of experienced chemists, chemical engineers, and instrumentation & electronics engineers work cohesively to drive advancements in flow chemistry.

With a strong focus on innovation, we help transition batch processes to continuous manufacturing, offering scalable and efficient solutions tailored to industry needs.

Chemistries Handled

Named

Reactions

- Aldol Condensation

- Claisen-Schmidt Condensation

- Knoevenagel Condensation

- Darzen Condensation

- Sandmeyer’s Reaction

- Fischer-Indole Synthesis

- Vilsmeier-Haack Reaction

Metal-Organic Reactions

- Grignard Reaction

- Turbo-Grignard Reaction

- Lithiation

Gas-Liquid-Solid Reactions

- Hydrogenation of Aromatic and Hetero-Aromatic Compounds

- Oxidation of Aromatic Compounds

- Ozonolysis of Alkenes

- Acetylation

Liquid-Liquid/Liquid-Solid Reactions

- Nitration of Alkanes, Alkenes,

and Aromatic Compounds - Sulfonation of Aromatic

Compounds - Diazotization and Coupling

- Aminations

- Dimerization Reactions

- Continuous Crystallizations

- Dehydration Reactions

(Acid Catalyzed) - Esterifications and Trans-esterifications

- Cracking of Vegetable Oils

- Bio-Oil Extraction and Hydrotreating

Processes Available for Tech Transfer

We offer a portfolio of patented continuous process technologies available for licensing and strategic partnership opportunities

- Nitration of Benzene to Nitrobenzene *

- Nitration of Toluene to Nitrotoluenes *

- Nitration of Chlorobenzene to Nitrochlorobenzenes *

- Nitration of Xylenes to Nitroxylenes *

- Nitration of Phenol to Nitrophenols *

- Nitration of Naphthalene to Nitronaphthalene *

- In-situ Synthesis of Peracetic Acid for Olefin Expoxidation

- Air-oxidation of o-Dichlorotoluene to o-Dichlorobenzoic acid

* All nitrations are carried out without the use of sulfuric acid

Chemistries in the Pipeline

- Flow Synthesis of Niacin and Niacinamide

- Ammoxidation of o-Chlorotoluene

- Nitrobenzene to Aniline via Liquid-phase Hydrogenation

- Flow Synthesis of Ethyl Hexyl Nitrate (EHN)

- Continuous Diazotization and Coupling for synthesis of various Azo Dyes

- Fragrance and Flavour Synthesis e.g Raspberry Ketone/ C16 Aldehyde

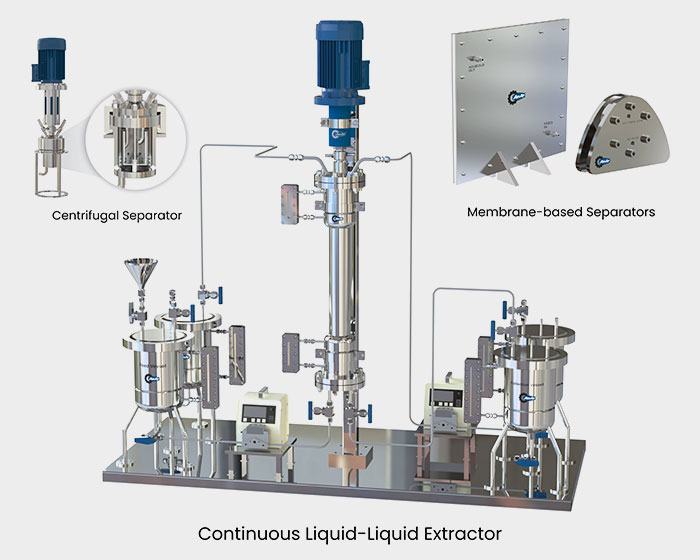

At Amar Flow Process Development Laboratory, we extend flow chemistry beyond reaction optimization by integrating continuous downstream processing solutions.

Our facility is equipped with continuous liquid-liquid extraction systems, including membrane-based and centrifugal separators, as well as a continuous liquid-liquid extractors for efficient phase separation. These technologies play a crucial role in flow chemistry by enabling seamless in-line purification, product recovery, and impurity removal without disrupting the continuous process.

Membrane-based extraction provides selective separation with high efficiency, while centrifugal extraction offers rapid phase disengagement, making them ideal for solvent extractions, reactive extractions, and product purification.