Flow Engineering Lab

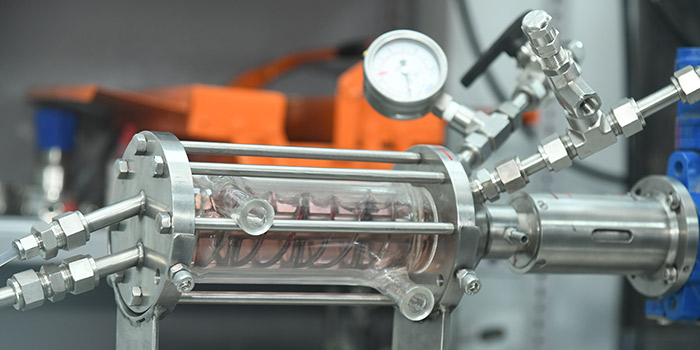

We have a dedicated flow engineering lab for rigorous characterization of our flow reactors, ensuring they are not just efficient but also scalable and reliable for industrial applications.

We conduct comprehensive hydrodynamic studies, including pressure drop analysis, which helps optimize reactor design for minimal energy consumption while maintaining effective mixing and flow characteristics.

Our heat and mass transfer studies provide critical insights into thermal and mass transport efficiency, allowing us to fine-tune reactor performance for highly exothermic, endothermic, and diffusion-limited reactions.

Additionally, residence time distribution (RTD) studies help us quantify flow behavior, assess dispersion effects, and determine the degree of plug flow or back-mixing, which are key factors in process predictability and scale-up.

Beyond experimental characterization, we leverage computational fluid dynamics (CFD) simulations to visualize internal flow patterns, mixing dynamics, and energy dissipation within our reactors.

By combining experimental validation with advanced modeling, we create precisely engineered flow reactors that deliver superior efficiency, reproducibility, and industrial-scale implementation.

For a deeper look into our reactor characterization studies, including detailed pressure drop data, heat and mass transfer coefficients, residence time distribution plots, and CFD analysis, please contact us.